I have gotten a few requests for plans and dimensions for my binding jig, so I finally got around to it. I only operate in the metric system, sorry! To calculate the dimensions in inches, just remember that 1" = 25,4 mm.

I made mine with materials I had on hand, and that was some cheap bearings, threaded rod and some 15 mm acrylic scraps. Some people have commented that acrylic is difficult, even scary to shape and that a polycarbonate like Lexan is better for a jig like this. I don't find acrylic that hard to shape, but it can chip if you are not careful, so wear goggles! Of course, you can also use plywood, aluminum or whatever, and you will have to adjust it to your trimmer and your needs. I use a 400W Hitachi trimmer.

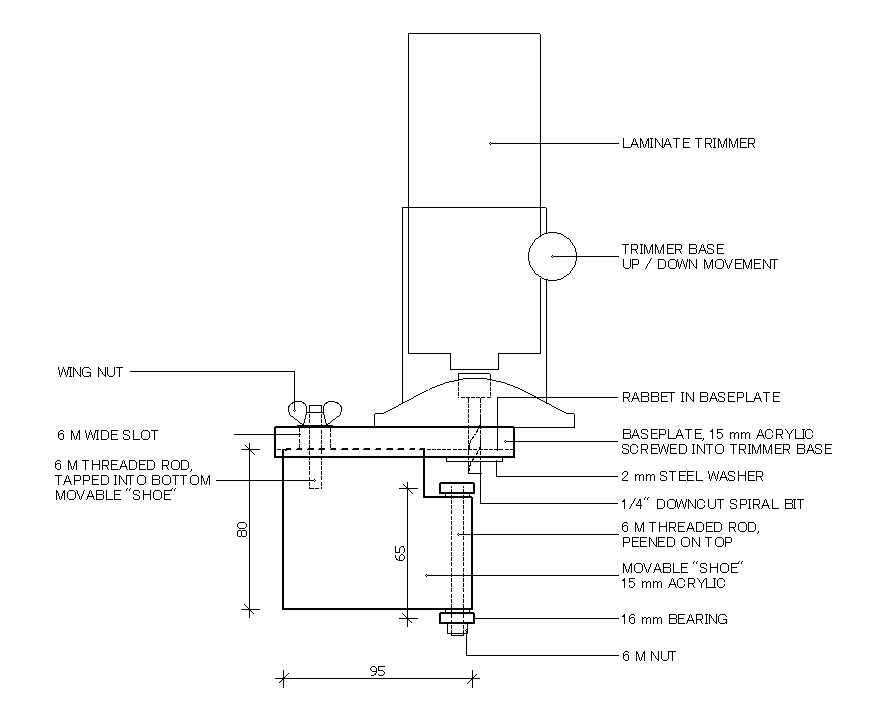

Here is a quick and dirty elevation (I can e-mail the .pln or .dwg or .dxf to anyone interested).

Here is how I operate the jig:

The binding rabbet width is adjusted by moving the bottom part (movable "shoe") in or out in a rabbet in the top part (base plate). A wing nut and a screw that is tapped into the movable bottom part secure it to the fixed upper part. The binding rabbet height is adjusted on the trimmer base adjustment screw. I use 1/4" carbide down cut bits (from LMI) with this jig, so the cut is very clean. The bit protrudes through a washer glued to the base which makes sure you only register on the edge of the top or back plate, meaning the plate’s radius will not interfere with the cut. I clamp this jig in a vise and rotate the guitar.

If you are clever you can probably also build a micro adjuster of some sort for the width adjustment. I just loosen the wing nut and tap lightly and test on scrap, no biggie.

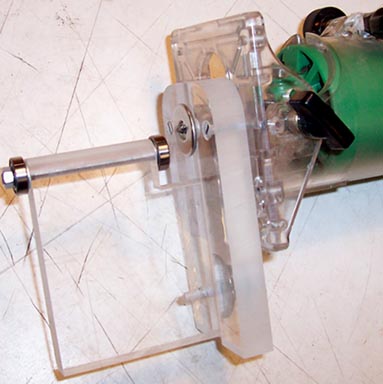

Here are a couple of snap shots again:

Front:

Side: